This is a demo store for testing purposes — no orders shall be fulfilled. Dismiss

PCB Prototype Technology & Laser Material Processing

LPKF Laser & Electronics is a leading provider of laser manufacturing solutions for powerful electronic systems.

Expert in development and production of printed circuit boards, solar modules, automotive parts and batteries.

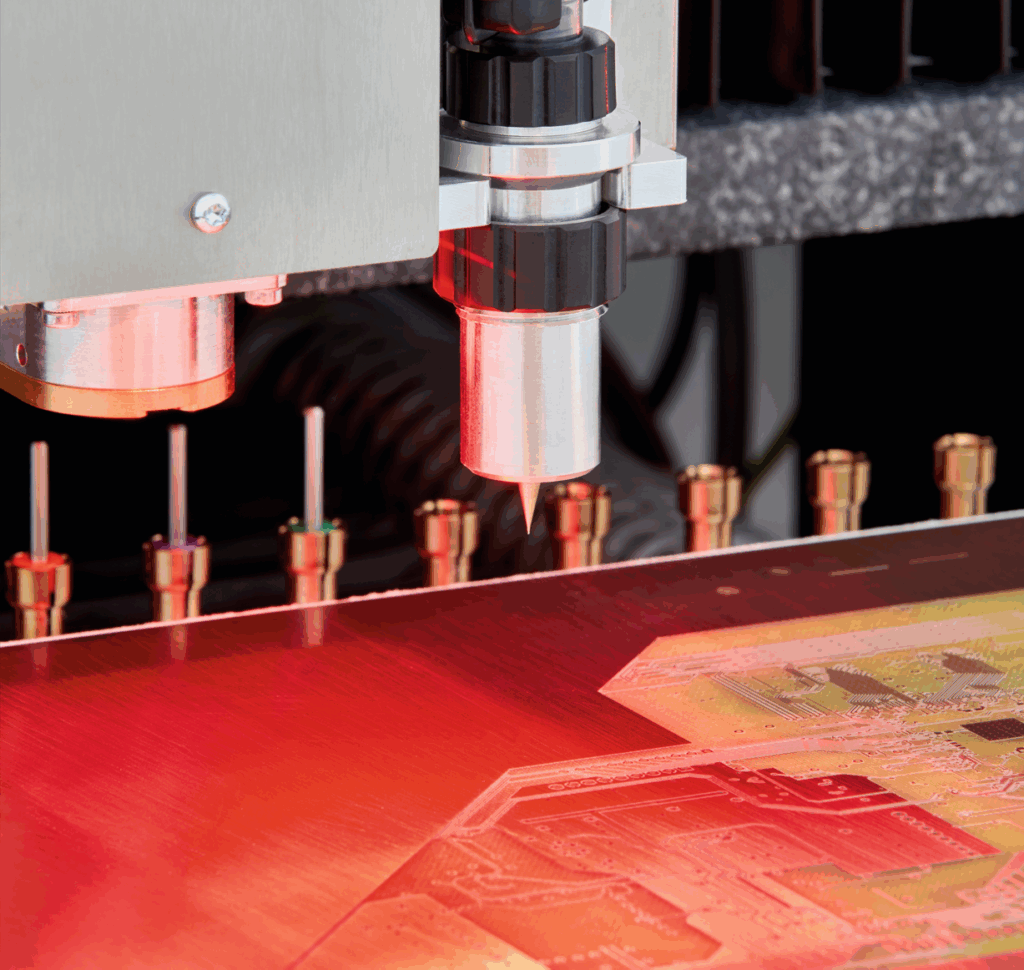

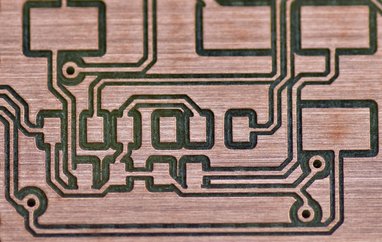

Precise, automated in-house PCB prototyping through high-speed milling, drilling, and engraving – turning your circuit designs into real boards within hours.

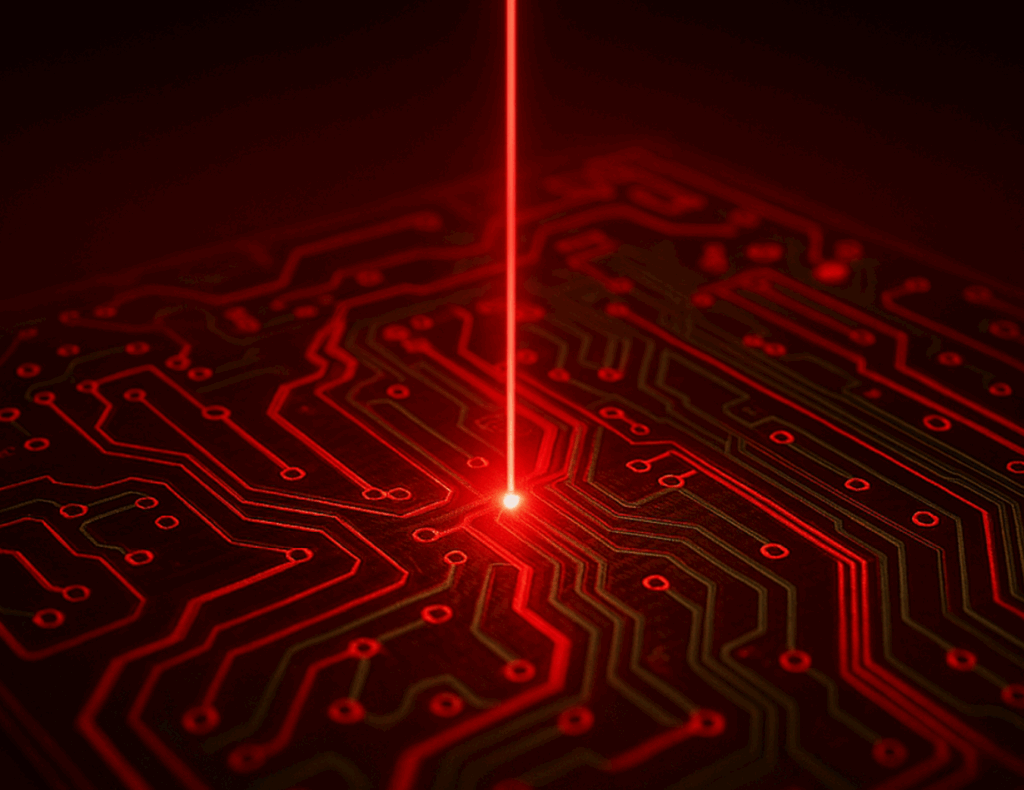

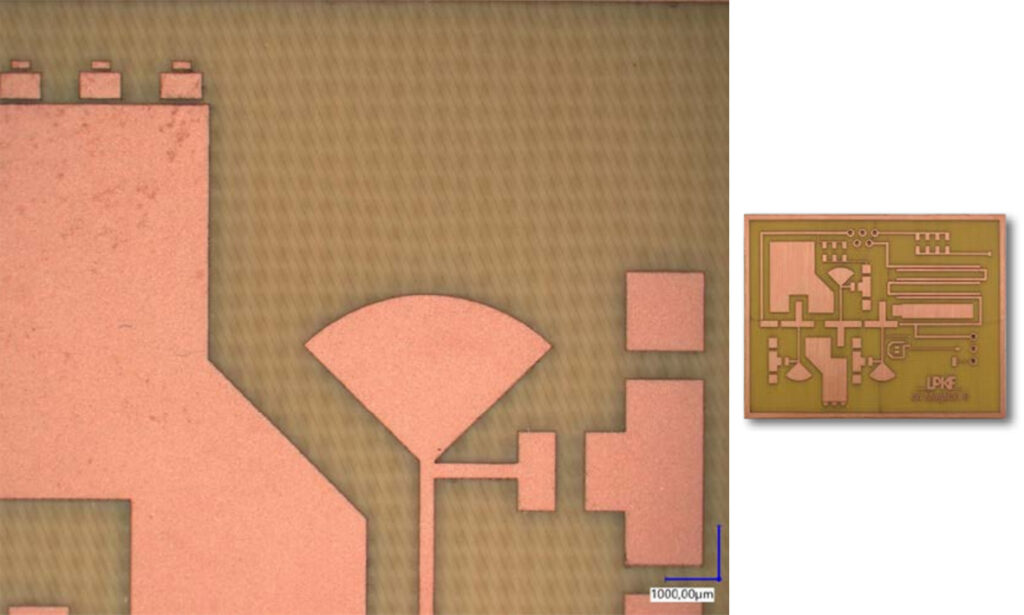

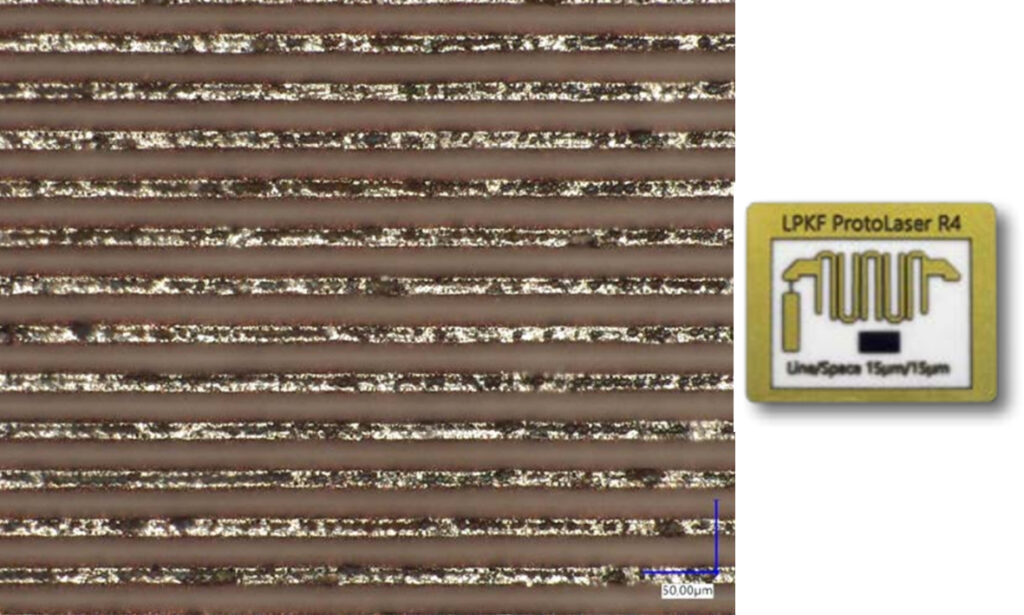

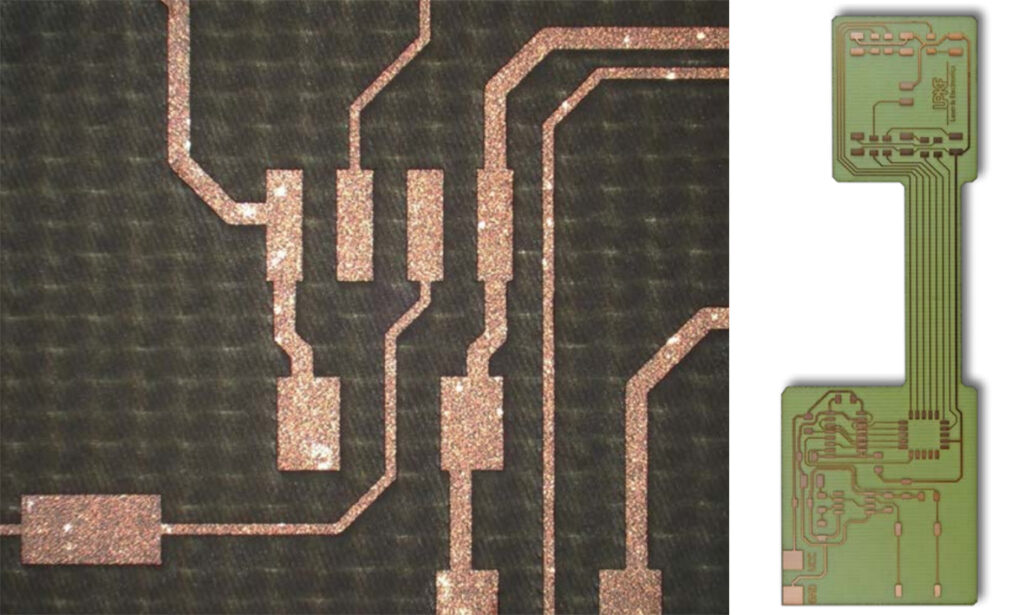

High-precision laser structuring system with different laser wavelengths and pulse frequencies designed for rapid prototyping and micromachining of PCBs, metals, and advanced materials.

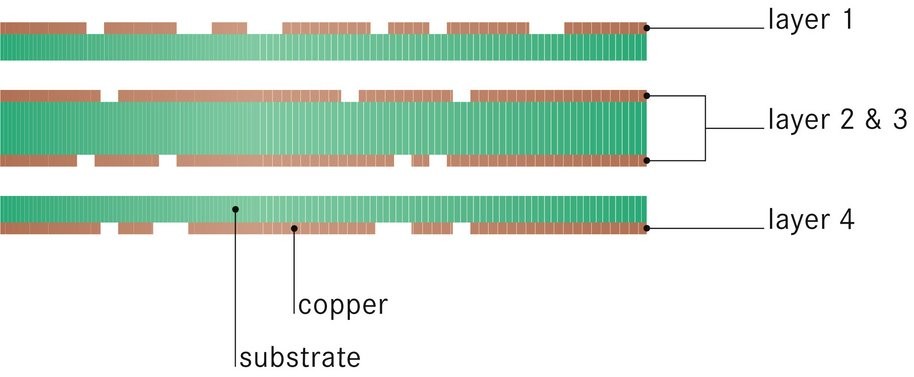

Production of up to eight layers in-house

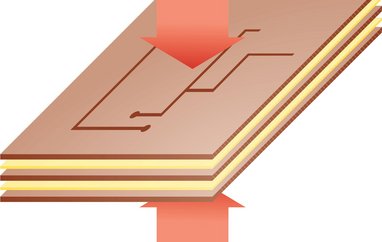

A multilayer is made up of multiple layers that are laminated together to form a printed circuit board. The outer layersof a multilayer are usually single-sided PCBs, whereas the inner layers are double-sided materials. Insulating layers, so-called prepregs,are inserted between the conductive layers. Up to four layers can be through-hole plated in a chemical-free process. For electrical connection of up to eight layers through-hole electroplating is recommended.

Three steps to a multi-layer board

Structuring

An LPKF ProtoMat or ProtoLaser structures circuit traces directly from layout data, using automatic tool changing and camera-based fiducial alignment to process each layer with minimal manual intervention.

Lamination

The structured layers are stacked with prepregs that provide insulation and bond during lamination. The LPKF hydraulic press system delivers reliable lamination (even for HF multilayers) using preset process profiles.

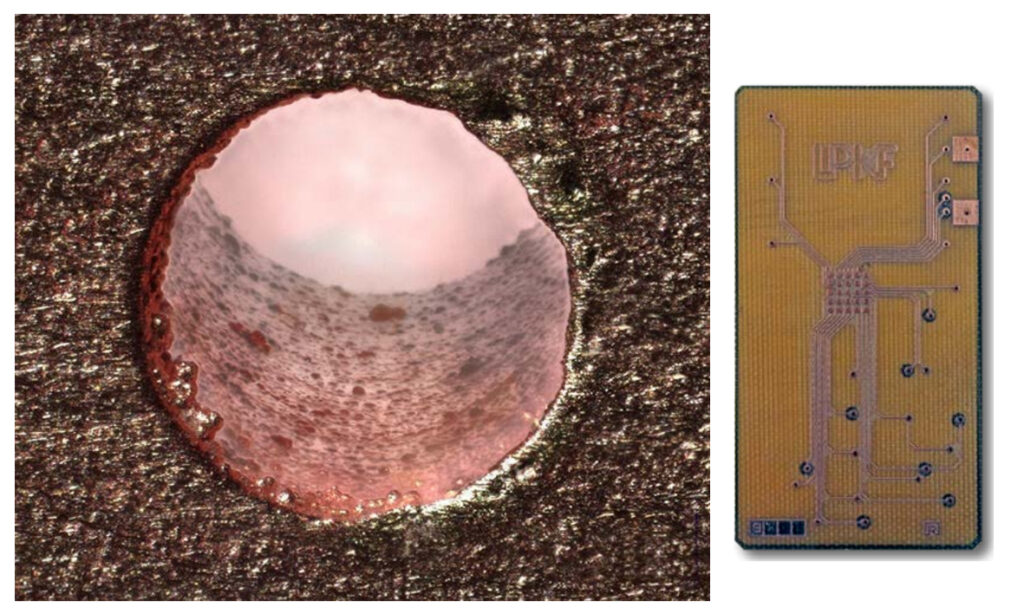

Through-hole plating

Interlayer electrical connections complete the conductor structure. The through-holes are drilled and then metallized using a chemical-free conductive paste; for boards with more than four layers, conventional electroplating is recommended.

PCB process add-ons extend your in-house prototyping from basic structuring to full production-grade functionality. They enable plated vias, durable surface protection, and clean assembly without outsourcing.

ProConduct

LPKF ProConduct is a system for chemical-free through-hole coating of double-sided and multilayer PCBs with paste. It is compact, fast, and easy to use.

Contac S4

For the wet chemical process, no knowledge of chemistry is needed; the LPKF Contac S4 system independently indicates the necessary process steps.

ProMask

Apply a durable solder mask in-house to protect copper surfaces, improve solderability, and achieve a clean, professional PCB finish.

ProLegend

Add high-contrast component markings directly to your prototype for clear identification and smooth, error-free assembly.

ProtoPrint S4

Screen-printing solder paste with consistent volume and alignment, ProtoPrint S4 ensures reliable SMD assembly on prototype PCBs.

ProtoFlow S4

A controlled reflow environment ensures consistent soldering quality, bringing your SMD assemblies to production-grade reliability.

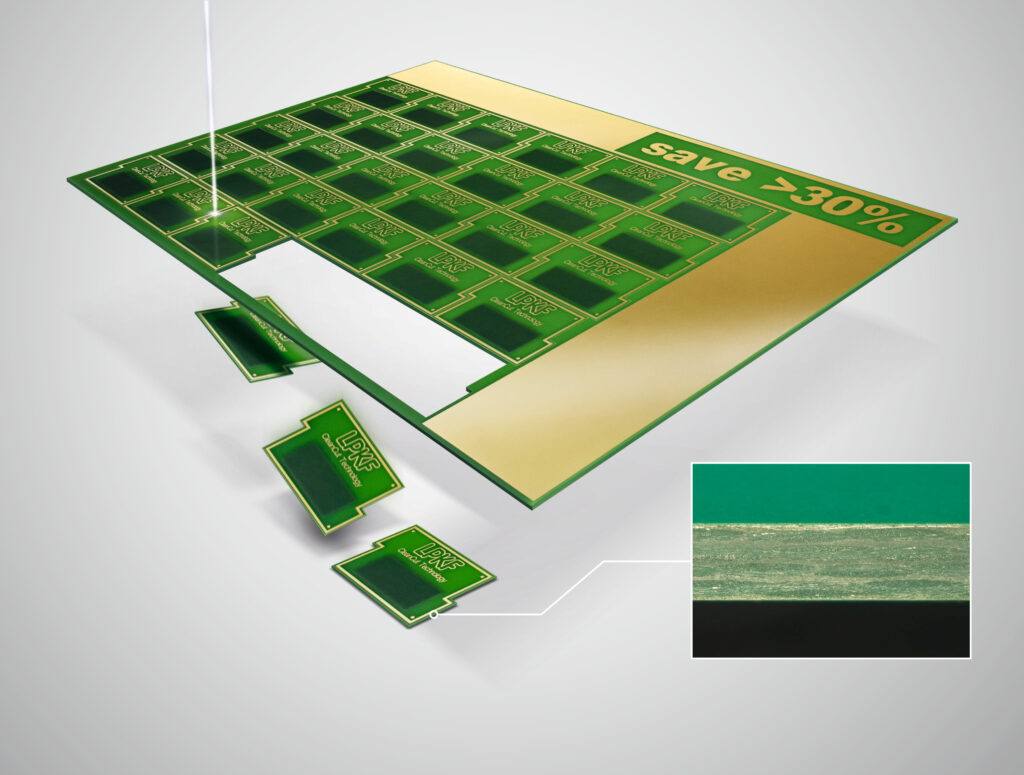

Laser depaneling is the most innovative technique for separating PCB from the panel and is differentiated from the classic separation methods in particular by its flexibility and stress-free processing.

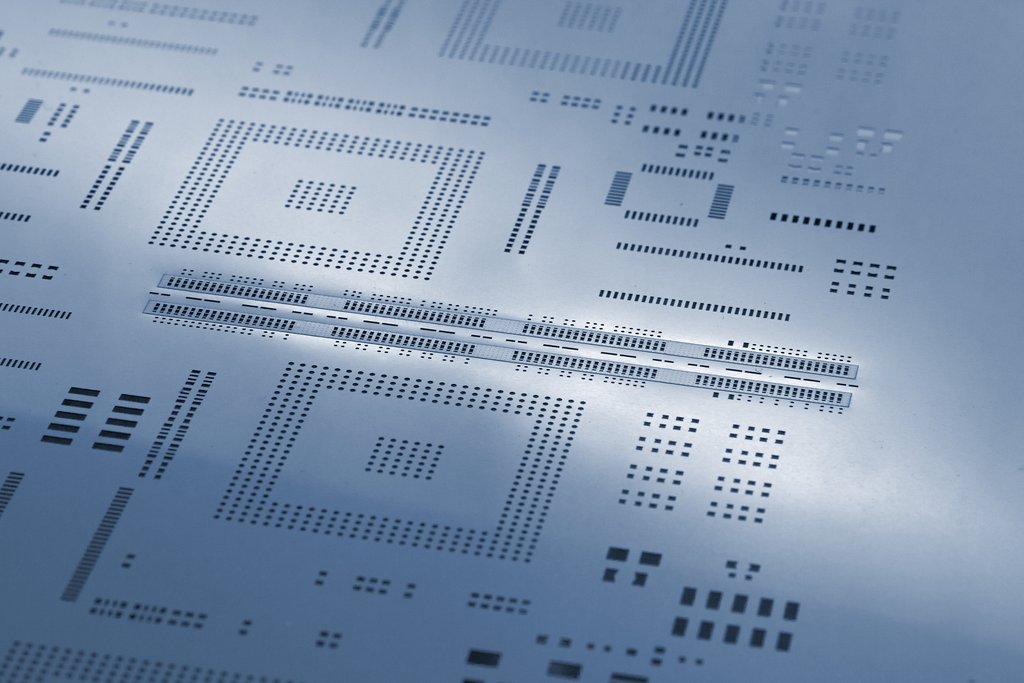

Stencil apertures with defined properties are essential for perfect solder printing results. LPKF StencilLasers are capable of cutting sheets from 20 μm up to 1 mm.

Joining plastic components in a way that is precise, reliable, and permanent – without adverse chemical, thermal, mechanical effects on the surrounding material? This is a simple job for LPKF laser welding machines!

Medical Device

From lab-on-chip systems to catheter and device housings, the process eliminates adhesives, prevents contamination, and ensures full regulatory monitoring.

Automotive Components

Welding of sensor housings, vehicle lighting modules, door‐lock assemblies, reservoir tanks, etc.

Consumer Products

Small, complex plastic assemblies such as smartphone casings, headphones, VR goggles, consumer appliances.

Electronics Housing

Waterproof PCB lighting housings have tight, hermetic seals around the PCB and lighting electronics.

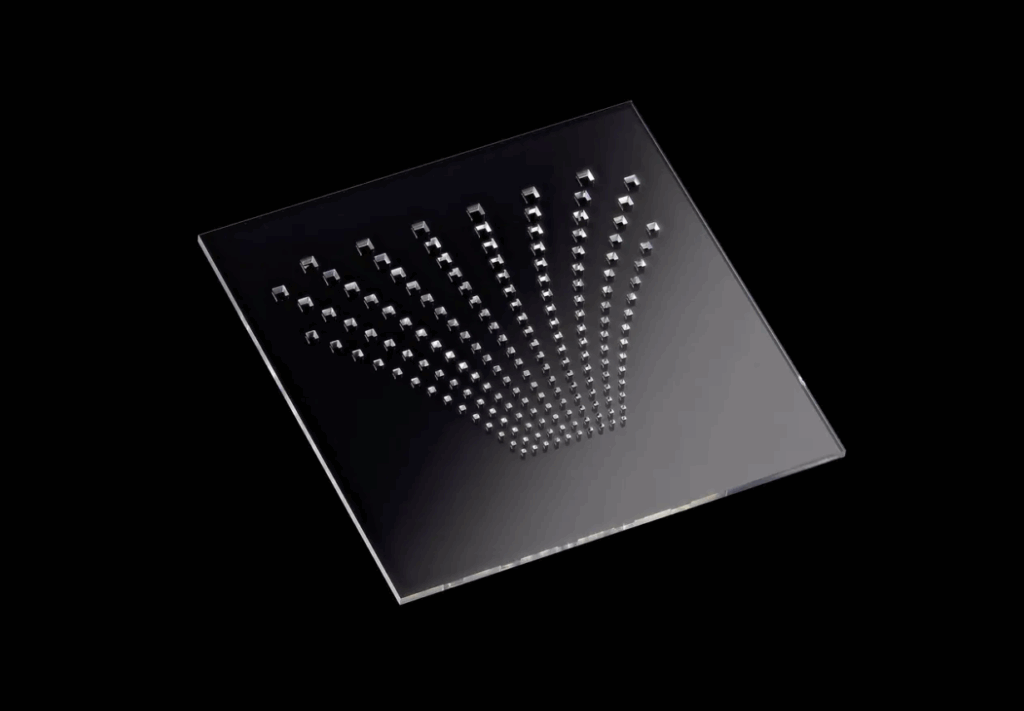

The LIDE® technology (Laser Induced Deep Etching) developed by LPKF is a new enabling technology for a wide range of applications in microsystems technology —— unlock zero-defect glass processing for your industry’s biggest challenges.

Semiconductor

Electronics

Automotive

Microfluidic Channels

Fast HF Sample

Ultra-fine Prototyping

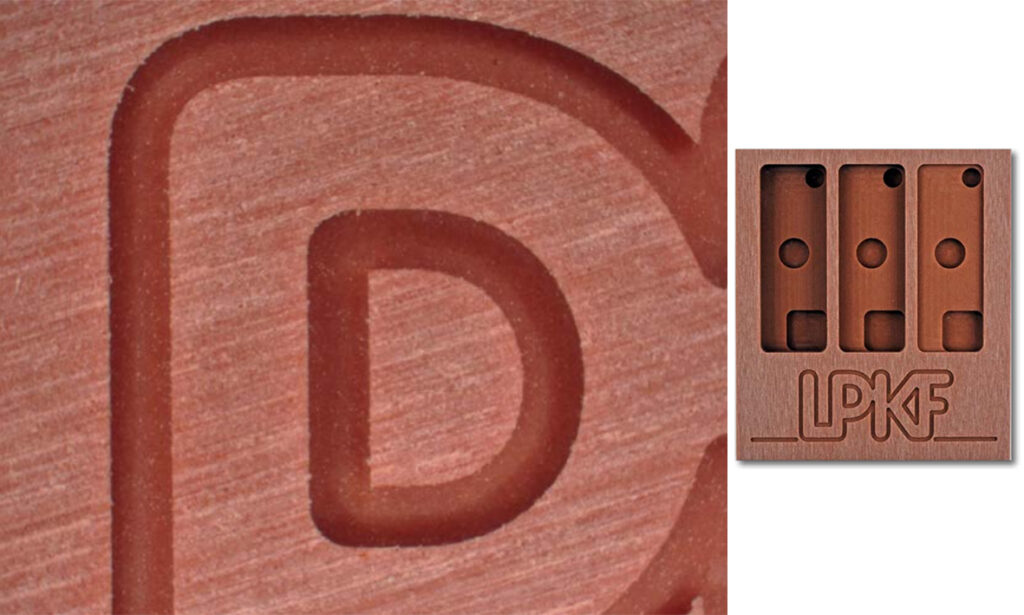

2.5 D Prototyping

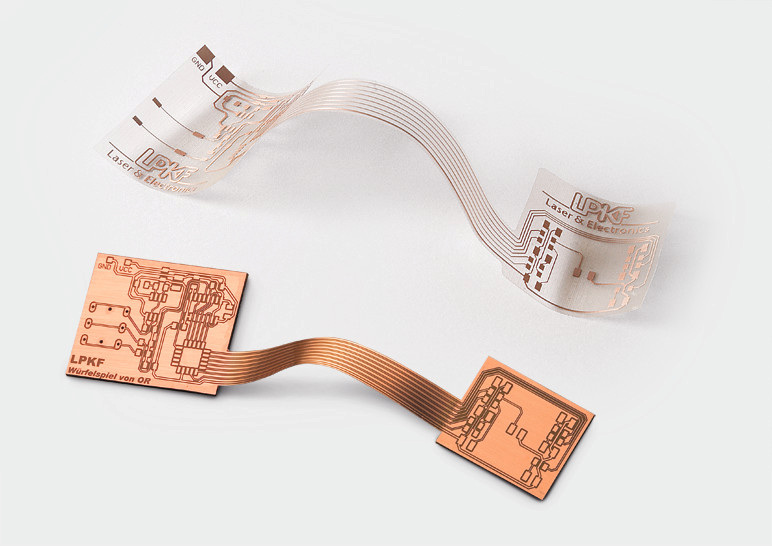

Flexible PCB

Multilayer THP Process

Flex-rigid PCB

5/23 Hunt Street North Parramatta NSW 2151 Australia

Tel: +61 2 9687 1880 / Fax: +61 2 9687 1881